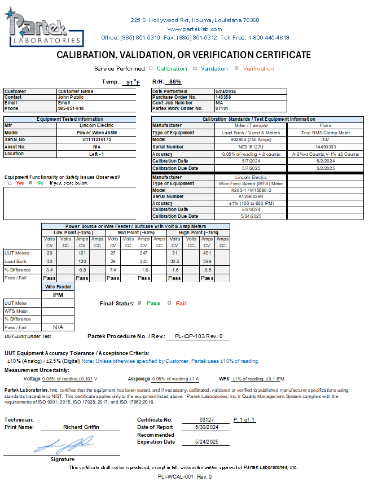

The process of calibrating, validating or verifying welding equipment involves connecting to a NIST traceable Load Bank, true RMS meters, and wire feed speed meters to measure voltage, amperage, wire feed speed, or other necessary parameters. These are all components of the welding machine that operators depend on to produce consistent welds, which is why it’s so important that all industrial welding machine calibration, validation and verification be performed by a professional.

At Partek Laboratories, we provide welding equipment calibration services for our manufacturing, fabrication and service customers. We ensure that the equipment is operating within recognized standards for safety and quality.

Why calibrate your welding equipment?

- Required by Industry code requirements such as AWS D1.5 (Bridge Welding Code)

- Customer requirements

- Quality Management System requirements (ISO 9001, API Q1, ISO 17662, etc.)

- Avoid unplanned downtime and optimize process efficiency

- Safety reasons

- The main reason for calibration is that even the best instruments drift and lose their ability to give accurate measurements. This drift makes calibration necessary.

Why Partek Laboratories?

- We have a well-documented procedure that is followed by our technicians along with producing traceable certificates for all calibrations.

- Our trained and knowledgeable technicians come to you and utilize NIST traceable certified equipment. Your welding equipment doesn’t have to leave the shop floor. Once it’s been calibrated, it can immediately be put back to work.

- We are an independent party. Having an outside party calibrate your machines will prove to your customers that you’re serious about Quality Control.

- We can handle any welding power source up to 1000 Amps. The brand or quantity makes no difference.

- Low cost and high value service!

Contact us for a quote or to schedule our service!