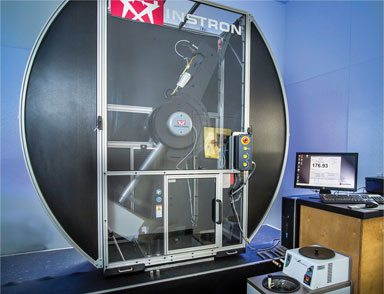

550 ft-lb. motorized Pendulum Impact Testing System

Partek Laboratories is proud to offer some of the highest capacity and most technologically advanced equipment along the Gulf Coast to determine the mechanical properties of all materials, including parent metals and welds. Deepwater/subsea fabrication companies and clients from other marine, pipeline, and nuclear energy industries rely on Partek’s expert metallurgists to certify that materials and welding procedures satisfy the requirements of harsh operating environments and demanding work conditions. All testing is conducted to customer specifications and/or national codes. Partek also offers portable equipment to perform hardness testing at a client’s facility or job site.

Download Mechanical Testing Brochure PDF

In our precision machine shop, Partek machinists produce both standard

and specialized specimens for mechanical testing.

Facility Features and Equipment:

- Fully equipped machine shop to produce precision test specimens

- Advanced laboratory includes:

- 337,500-lb. Tensile/Compression Testers

- 550 ft-lb. motorized Pendulum Impact Testing Systems

- Optical Emission Spectrometer

- Optical Microscopes

- Metallurgical Microscope/Etchant

Capabilities:

- Compression Testing

- Bond Testing

- Charpy Impact Testing

- Drop Weight Testing

- Hardness Testing

- Tensile Testing – Yield Strength, Ultimate Tensile, Elongation

337,500-lb. Tensile/Compression Tester