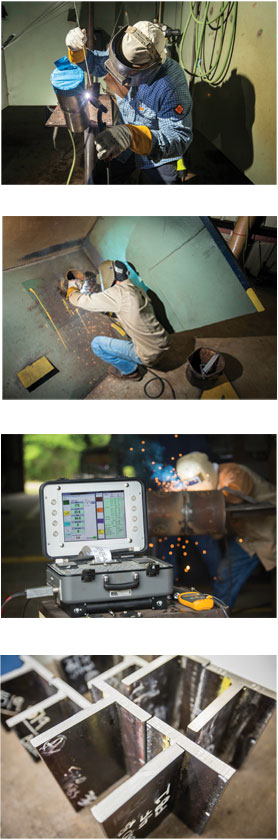

Partek is the Gulf Coast’s trusted source for welding procedure development and certification of welder performance, all designed to promote safety and quality workmanship on your job site. At our Welding Qualification Center, Partek welding engineers develop trusted welding procedures for clients working in a variety of high-performance industries like deepwater drilling and production, fabrication, shipbuilding, petrochemical, pipelines, U.S. Dept. of Defense, and nuclear energy. We also provide welding procedure witnessing and monitoring by AWS Certified Welding Inspectors (CWI) conducted to customer specifications and national and international codes. Additionally, Partek tests and certifies welders on specific processes to meet our customers’ requirements, including limited space access.

Welding Procedures

Partek is experienced and equipped to develop and test welding procedures for exotic metals critical to the deepwater/subsea fabrication and pipeline industries. Welding Procedure Witnessing and Monitoring by an AWS CWI is conducted to ensure that welders can successfully perform the welding procedure unique to each client, project, material, or application.

Welder Qualifications

Our Welding Qualification Center has 29 welding booths and 4 fitter booths (plate and pipe) to test a full range of welder qualifications.

Processes

- SMAW

- GTAW (TIG)

- GMAW (MIG)

- FCAW

Pipe

- 6 GR

- 6G

- 5G

- 2G

- Limited Access

Plate Positions

- 1G – Flat

- 2G – Horizontal

- 3G – Vertical

- 4G – Overhead

- Limited Access